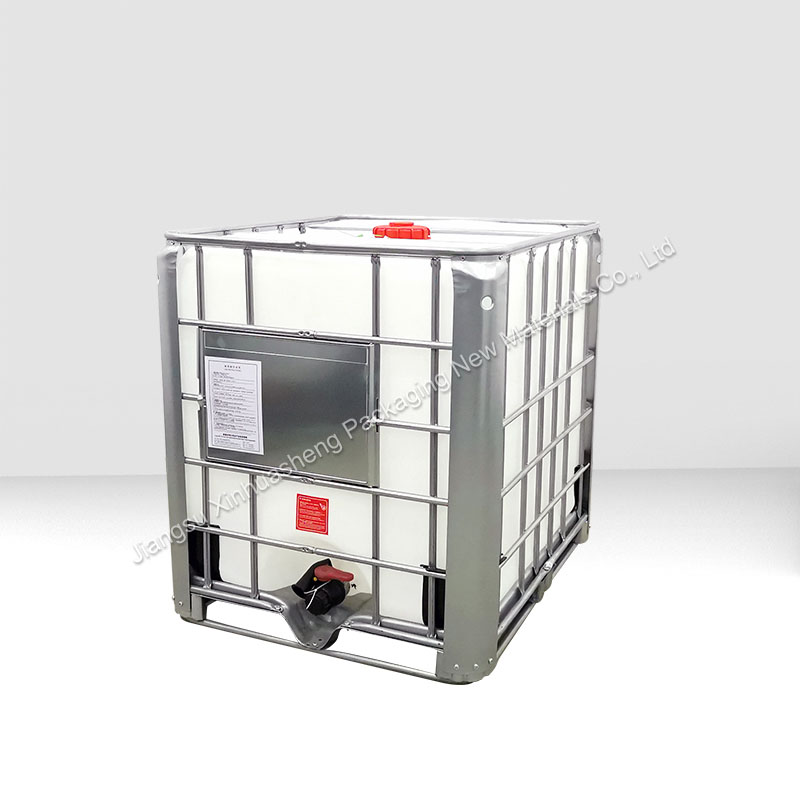

1000L Hoisting Intermediate Bulk Containers

XHS is a leading 1000L Hoisting Intermediate Bulk Containers manufacturer, supplier and exporter in China. Adhering to the pursuit of perfect quality of products, maximum design, high quality of these raw materials, high performance and competitive price is what every customer wants and can also provide for you. Of course, what is also essential is our comprehensive service.

Send Inquiry

Jiangsu Xinhuasheng produces different types of IBC tanks,For example, the 1000L Hoisting Intermediate Bulk Containers is an essential tool for modern transportation and transportation of materials and products. The inner liner of the container barrel is combined with the default steel frame, and the inner high-bracket high-density polyethylene blow molding is formed, which has high strength, corrosion resistance and good sanitation.

XHS 1000L Hoisting Intermediate Bulk Containers Introduction

We are a manufacturer with many years of working experience in IBC TANK Metal Accessories,IBC TANK Finished Barrel IBC TANK(1000L Hoisting Intermediate Bulk Containers),IBC TANK Valve Interface,IBC TANK Plastic Accessories and Others,etc. We also help customers develop new molds for new products.

XHS 1000L Hoisting Intermediate Bulk Containers Parameter (Specification)

|

1000L Hoisting Intermediate Bulk Containers |

|

|

XHS 1000L Hoisting Intermediate Bulk Containers Feature And Application

1000L Hoisting Intermediate Bulk Containers is a modern warehousing, transportation of liquid products, the necessary tools. The container barrel inner container and galvanized steel framework combination, the content of high molecular weight high density polyethylene blow molding, high strength, corrosion resistance, good health.

XHS 1000L Hoisting Intermediate Bulk Containers Details

Hot selling 1000L Hoisting Intermediate Bulk Containers

1000L Hoisting Intermediate Bulk Containers is a modern warehousing, transportation of liquid products, the necessary tools.

Standard breathing top cover - when the barrel reaches a certain pressure, it will automatically exhaust and decompress

Corner wrapping design of the inner container Anti-collision - the bottom of the container is equipped with wrapping corners to better protect the liner of the container

Outer frame structure - the horizontal tubes and vertical tubes of the ton bucket frame are all round tube embossed welding, which is not easy to de-solder, which is stronger than the square tube welding of ordinary manufacturers and has a longer service life

Valve design - the ton barrel is equipped with standard valves, liquid delivery and discharge pipes, and the combined discharge is more convenient